MEDICAL GAS HIGH / LOW PRESSURE SWITCH

Medical gas mainline pressure switches are to monitor all main line medical gas pressure or vacuum (HgV), and sends a dry contact signal to a remote medical gas master alarm panel. The pressure is to be installed imidiately downstream of the mainline/source valve per NFPA 99, and are to be wired as normally closed on all circuts. Some master alarm need certain pressure switches, so pleas check with us before you order.

NOTES:

NOTES:

- Standard High / Low pressure switch are for 0-100 psi (the standard setting is 40/60 psi)

- High pressure switches are typically found on Nitrogen and Insturment Air lines where pressure is 100-180 psi. 2 switches will be required to monitor a high and a low for high pressure applications (80 psi or higher)

- Reserve system switches are for reserve systems, commonly found on cryogenic systems, in-building emergency reserve systems, and back up source systems

- All pressure switches come with a gauge and are on demand checks

Product Files

- Cut Sheet--Amico Medical Gas High Low Pressure Switch

- Cut Sheet--Amico Medical Gas Vacuum Low Pressure Switch

- Cut Sheet--Amico Gas Nitrogen High Low Pressure Switch Assembly with Gauge

- Cut Sheet--Amico Medical Gas Reserve Pressure Switch

- Amico Medical Gas Mainline Pressure Switch with Gauge Instrument Air

- Amico Medical Gas Pressure Switch Catalog

General Specifications:

- Pressure Gauge Assembly for the medical gas alarm system shall incorporate a U.L. Listed single pole double throw snap-action micro switch. The pressure switch shall be prewired with six color coded leads. Normally open or normally closed circuitry shall be field-selected to be compatible with the medical gas alarm system design.

- Electrical rating shall be 10 amperes at 120 volt AC. The pressure switch shall be tested at 160 psi with an adjustable range of .5 to 80 psi and have external calibration dials with tamper- proof cover. Factory settings shall be 40 psi and 60 psi for pressuregases.

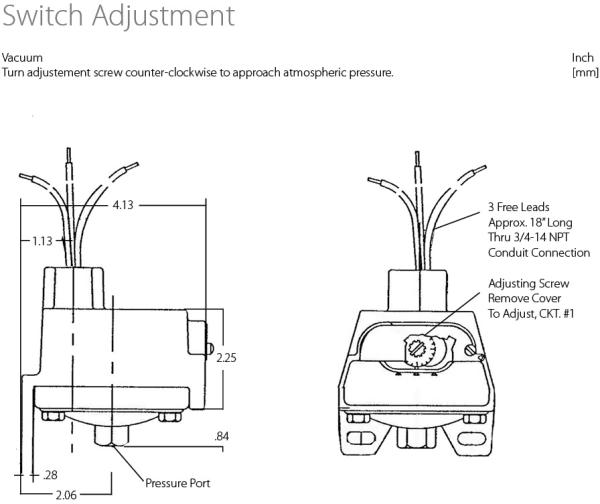

- The switch enclosure shall be a Nema 4 water tight housing with mounting bracket, 1/4” FNPT bottom inlet gas service line connection, and 3/4” FNPT top inlet conduit. A gauge shall be incorporated after the pressure switch. A gas specific DISS nut and nipple shall be attached to the bottom of the gauge.

- The Pressure Gauge Assembly will then be mounted directly to a gas specific DISS demand check (provided by Amico) directly onto the pipeline. The demand check shall have a 1/4” Male NPT connection.

Submit Quote

Submit Quote View RFQ

View RFQ