Manifolds

What do Medical Gas Manifolds Do?

Medical gas manifolds are an important part of the medical gas delivery system at any facility. Medical gas manifolds might consist of Oxygen, Medical Air, Nitrous Oxide, Carbon Dioxide, Nitrogen, or Instrument air. The manifold itself is used to provide the facility with a consistent flow of gas at a constant pressure rate. Most importantly, this ensures there is always a steady gas supply and that the pressure is safe for patient use. Medical gas manifolds have built-in regulators. These regulators monitor the supply line pressure and the amount of pressure left in the cylinders. The manifold is also connected to a remote alarm in a monitored location. The alarm alerts the facility when there is a low gas pressure reading or a change over alarm. This alert will let the facility know if it’s time to replace the empty cylinders.

How do they work?

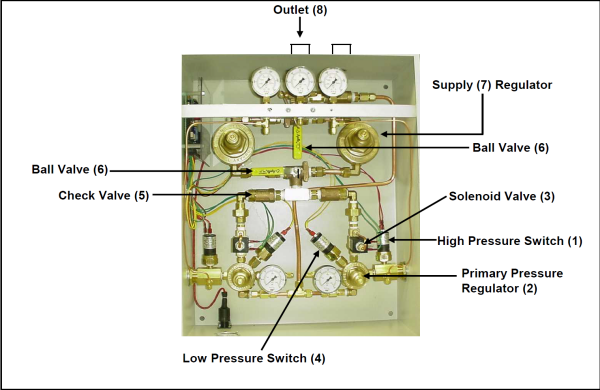

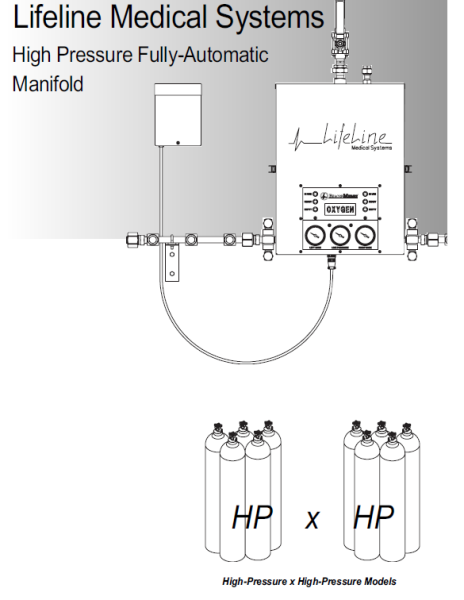

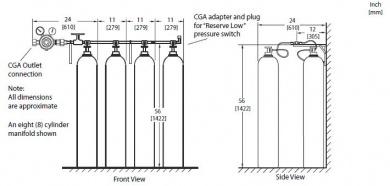

Maniolds control the flow a and pressure of the high pressure tanks. The high pressure tanks are connected to a header bar, which connections to the manifold which is made up of a series of regulators and check valves to control the supply.

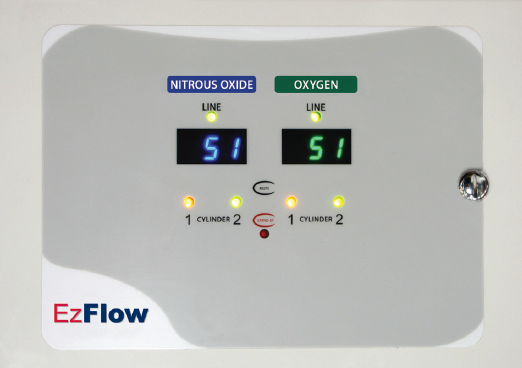

Medical gas manifolds typically have redundant components in the case of a falure or maintenance, the service of gas will not be disrupted. Medical Gas manifolds alternate between the primary and secondary bank as it cycles through the connected cylinders. Most medical manifold systems are required to have a local signal and guages showing the pressure and "bank in use status." NFPA 99 manifolds are required to have this. LED light will indicate if the cylinder connected to the bank is “in-use”, “reserve”, or “empty.” Some manifolds used in labs are not required to have the same features and a fully medical grade manifold.

In medical facilities with patients, the medical gas manifold will have a alarm the connected to the manifold to indicated with the primary bank in use is empty, and an additional alarm that indicates if the main line supply pressure and supply PSI is low or high. This alert will let the facility know if the cylinders are empty and need to be changed out. If the cylinders are not empty, then the facility may have a gas leak somewhere down the pipeline. A medical gas professional will need to be contacted to help locate the gas leak.

Types of Oxygen Manifolds

There are a few types of manifolds available for different facility applications. Below is a breakdown of the types of oxygen manifolds available:

- Automatic Digital Manifold – automatically changes over to the reserve cylinder when the in-use cylinder is empty. This will not create a fluctuation in the gas line pressure. The pressure readings for left bank, right bank, and supply are displayed digitally and are easy to read. There is no manual reset needed when hooking up new cylinders.

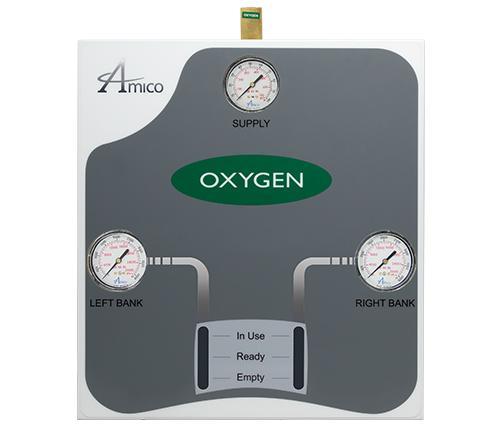

- Automatic Analog Manifold – automatically changes over to the reserve oxygen tank when the in-use oxygen tank is empty. This does not cause any fluctuations in the gas line pressure. No manual reset needed when connecting new cylinders. The pressure readings for left bank, right bank, and supply are displayed on pressure gauges (analog).

- Semi Automatic Manifold – switches over from in-use tank to reserve tank automatically. Requires a manual reset when changing out cylinders. Pressure readings for the left bank, right bank, and supply line are displayed on gauges (analog).

- Semi Automatic Simplex Manifold – has a very simple design. The header bar assembly is included, along with a regulator at the end to monitor pressure readings. Often used as a reserve manifold.

- NEMA-4 – this manifold comes with a special housing rated for outdoor use. The manifold can be either automatic, digital or automatic, analog and work the same way.

Amico’s medical oxygen manifolds are reliable, durable, and comply with NFPA 99 code standards. We also carry Amico manifolds for nitrous oxide, medical air, and carbon dioxide.

For more information on your selected oxygen manifold, click the “Specifications” tab and you will be directed to the manufacturer’s product spec sheet.

Submit Quote

Submit Quote View RFQ

View RFQ