Ethernet-Enabled NFPA Medical Gas Manifold

The Amico Ethernet manifold is dome loaded (no shuttle valve), and can be remotely monitored on the internet. This is ideal for medical facilities that want to monitor the manifold remotely.

Note: Oxygen manifold require the copper pigtails per NFPA 99. Make a note of the total wall space in the comment section when requesting a quote.

Features:

SPECIFY THE TOTAL LENGTH REQUIRMENTS IN THE COMMENT SECTION WHEN ORDERING

Cut Sheet- Amico Ethernet Manifold

Note: Oxygen manifold require the copper pigtails per NFPA 99. Make a note of the total wall space in the comment section when requesting a quote.

Features:

- Fully automatic with dual line regulators

- Input power 110 VAC to 240 VAC, 50 to 60 HZ

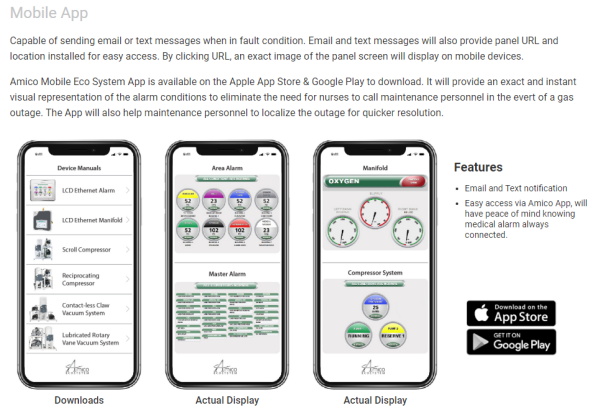

- Control panel incorporates a one of a kind LCD monitor

- The LCD monitor shall be capable of displaying an exact replica of the gas pressures on a computer screen via facility’s Ethernetor internet. In addition, an exact image of the gas pressures can be displayed on a mobile device via WiFi

- 3/4" (19 mm) isolation valve for supply line

- Manifold complies with NFPA 99

SPECIFY THE TOTAL LENGTH REQUIRMENTS IN THE COMMENT SECTION WHEN ORDERING

Cut Sheet- Amico Ethernet Manifold

General Specifications:

The manifold shall be a fully automatic type and shall switch from “Bank In Use” to “Reserve Bank” without fluctuation in the final line pressure.

After the switchover, the “Reserve Bank” shall then become the “Bank in Use” and the “Bank in Use” shall become the “Reserve Bank”.

The control panel incorporates an LCD screen that reflects the supply line and bank pressures. The manifold is Ethernet capable for convenient viewing of the gas pressures, remotely or wirelessly, anywhere in the building. When the gas pressures are normal, the display will reflect a normal condition at the top of the LCD screen. When a bank has depleted, the display will reflect a red window at the top of the LCD screen indicating and side that is empty. The manifold includes a built in buzzer to notify an alarm condition and has a dry contact for remote monitoring. The intermediate and final line relief valves are internally connected to a common vent port terminating into a 1/2" (13 mm) FNPT pipe.

PLEASE NOTE:

• The manifold shall be equipped with a 3/4" (19 mm) outlet shutoff valve. The valve comes complete with a 3/4" (19 mm) type “K” 6-3/4" (172 mm) long pipe extensions and 1/8" (3 mm) port for an optional pressure switch.

• The header bars shall be equipped with high pressure shutoff valves outside the cabinet to allow for emergency isolation of the header bars. The header bar shall incorporate integral check valves for each station.

• The manifold is equipped with pressure transducers, which sends information to the main circuit board for operation of the fail-safe relay which transmits a remote signal to the master alarm or buzzer.

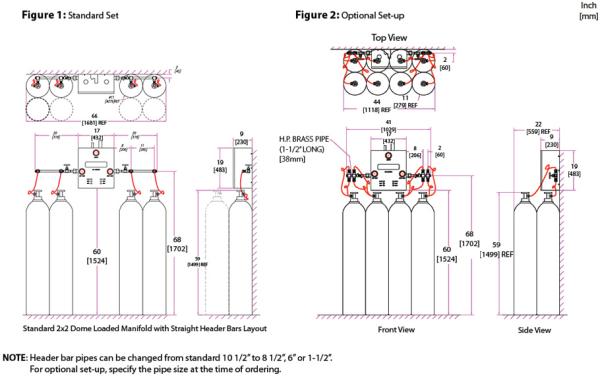

• The header bar mounting brackets are only supplied with more than 10 cylinders, for a staggered header bar, and more than 4 cylinders for a straight header bar.

• The manifold cabinet has a NEMA-1 rating for general purpose.

• Optional heaters are available for N₂O and CO₂ manifolds.

• The flow capacity of a nitrous oxide and carbon dioxide manifold depends upon the environmental conditions at the installation site and the number of cylinders in service. Installing them in a location that exposes it to an ambient temperature below 32˚F (0˚C) is not recommended.

• The manifold shall be installed in accordance with the requirements stated by NFPA 99, CGA, and all applicable local codes. Amico recommends the control cabinet be located at an installation site protected from rain, snow and direct sunlight.

• CGA gas specific header bar with integral check valves and cylinder pigtail assemblies (to be ordered separately).

Flow capacity:

• Oxygen, Medical Air, Nitrous Oxide and Carbon Dioxide – 4,500 SCFH (2,123 L/min)

• Nitrogen and Instrument Air – 6,000 SCFH (2,831 L/min)

The manifold shall be a fully automatic type and shall switch from “Bank In Use” to “Reserve Bank” without fluctuation in the final line pressure.

After the switchover, the “Reserve Bank” shall then become the “Bank in Use” and the “Bank in Use” shall become the “Reserve Bank”.

The control panel incorporates an LCD screen that reflects the supply line and bank pressures. The manifold is Ethernet capable for convenient viewing of the gas pressures, remotely or wirelessly, anywhere in the building. When the gas pressures are normal, the display will reflect a normal condition at the top of the LCD screen. When a bank has depleted, the display will reflect a red window at the top of the LCD screen indicating and side that is empty. The manifold includes a built in buzzer to notify an alarm condition and has a dry contact for remote monitoring. The intermediate and final line relief valves are internally connected to a common vent port terminating into a 1/2" (13 mm) FNPT pipe.

PLEASE NOTE:

• The manifold shall be equipped with a 3/4" (19 mm) outlet shutoff valve. The valve comes complete with a 3/4" (19 mm) type “K” 6-3/4" (172 mm) long pipe extensions and 1/8" (3 mm) port for an optional pressure switch.

• The header bars shall be equipped with high pressure shutoff valves outside the cabinet to allow for emergency isolation of the header bars. The header bar shall incorporate integral check valves for each station.

• The manifold is equipped with pressure transducers, which sends information to the main circuit board for operation of the fail-safe relay which transmits a remote signal to the master alarm or buzzer.

• The header bar mounting brackets are only supplied with more than 10 cylinders, for a staggered header bar, and more than 4 cylinders for a straight header bar.

• The manifold cabinet has a NEMA-1 rating for general purpose.

• Optional heaters are available for N₂O and CO₂ manifolds.

• The flow capacity of a nitrous oxide and carbon dioxide manifold depends upon the environmental conditions at the installation site and the number of cylinders in service. Installing them in a location that exposes it to an ambient temperature below 32˚F (0˚C) is not recommended.

• The manifold shall be installed in accordance with the requirements stated by NFPA 99, CGA, and all applicable local codes. Amico recommends the control cabinet be located at an installation site protected from rain, snow and direct sunlight.

• CGA gas specific header bar with integral check valves and cylinder pigtail assemblies (to be ordered separately).

Flow capacity:

• Oxygen, Medical Air, Nitrous Oxide and Carbon Dioxide – 4,500 SCFH (2,123 L/min)

• Nitrogen and Instrument Air – 6,000 SCFH (2,831 L/min)

Submit Quote

Submit Quote View RFQ

View RFQ

= Required

= Required