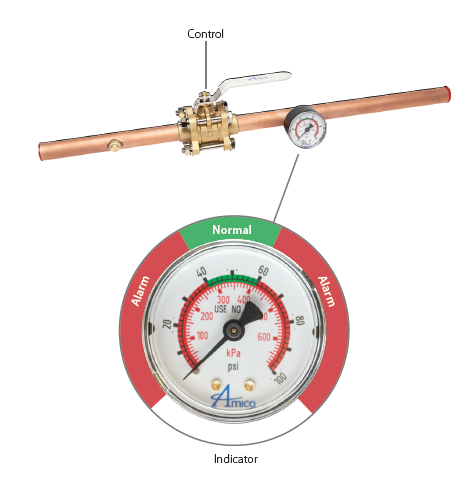

Medical Gas Zone Indicator Valve

The medical gas "zone indicator" valve is ideal for branch valves, main valves, source valves, riser valves, and inline valves. This valve increases safety in your medical gas system by providing a PSI reading at the valve. The gauge indicates the "green" zone which is the pressure required to meet NFPA 99 requirements, and the "red" or alarm zone corresponds with NFPA 99 alarming requirements.

Features:

Features:

- 100 PSI, 300 PSI, 30HgV Zone Alarm Indicator

- Serviceable design for ease of maintenance

- 100% Pressure tested

- Cleaned for oxygen service

- Available in sizes 1/2" to 2-1/2" (1.3 cm - 6.3 cm)

- Available in locking or non-locking

Product Files

General Specifications

Zone Indicator Control System shall consist of an alarm display for the zone and a control function. The Zone Indicator Control System shall be 3 piece ball-type design with a brass forging body and a chrome-plated brass ball for sizes 1/2" to 2-1/2" (1.3 cm - 6.3 cm). Ball seats, stem seals and stem washer shall be Reinforced Teflon (PTFE), with Viton stem and flange O-rings.

A blow-out proof stem shall be used and the zone indicator shall have a maximum pressure rating of 600 psi (4,137 kPa). The display shall indicate the status, RED for alarm condition and GREEN for normal condition. The Zone Indicator Control System shall be operated by a levertype handle requiring only a quarter turn to control the zone. Zone indicators shall be equipped with a type “K”, full port copper pipe stub extensions at both the inlet and outlet sides of the zone indicator port to facilitate installation. Zone Indicators shall be designed in such a manner that it can be “swung out” during installation so as to prevent damage due to heat transfer during the brazing operation.

Each Zone Indicator assembly shall be washed and degreased for medical gas service. Pipe stub extensions shall be capped at both ends. The zone indicator shall be supplied in a sealed plastic bag to prevent contamination prior to installation.

Zone Indicator Control System shall consist of an alarm display for the zone and a control function. The Zone Indicator Control System shall be 3 piece ball-type design with a brass forging body and a chrome-plated brass ball for sizes 1/2" to 2-1/2" (1.3 cm - 6.3 cm). Ball seats, stem seals and stem washer shall be Reinforced Teflon (PTFE), with Viton stem and flange O-rings.

A blow-out proof stem shall be used and the zone indicator shall have a maximum pressure rating of 600 psi (4,137 kPa). The display shall indicate the status, RED for alarm condition and GREEN for normal condition. The Zone Indicator Control System shall be operated by a levertype handle requiring only a quarter turn to control the zone. Zone indicators shall be equipped with a type “K”, full port copper pipe stub extensions at both the inlet and outlet sides of the zone indicator port to facilitate installation. Zone Indicators shall be designed in such a manner that it can be “swung out” during installation so as to prevent damage due to heat transfer during the brazing operation.

Each Zone Indicator assembly shall be washed and degreased for medical gas service. Pipe stub extensions shall be capped at both ends. The zone indicator shall be supplied in a sealed plastic bag to prevent contamination prior to installation.

Submit Quote

Submit Quote View RFQ

View RFQ