NFPA Medical Vacuum Moisture Trap

This medical and lab vacuum moisture trap is ideal to install in-line to protect your vacuum pumps from any debree or moisture that may be present in a medical vacuum line. They are availible up to 4" connection. It is recommended that valves are placed upstream and downstream of the trap so it can be isolated to drain any moisure and change the filter.

Benefits

Benefits

- Minimizes microbial contamination of vacuum pump oil and surrounding environment

- Visual pressure differential indication allows for real time monitoring and maintenance checks of the filter

- Biohazard labels improve safety and awareness at facility

- Increased surface area and large collection area maximizes contaminant holding capacity

- Low pressure drop design for reduced energy consumption over time

- Corrosion resistant and heavy duty materials of construction offer high performance and extended service life

- Isolation valve allows for quick and easy change out of glass flask for sterilization or disposal

- Equipped with pressure differential gauge for visual indication to service filter

- Easily incorporated into the medical gas distribution system piping allowing for a CE marking according to the

- Medical Devices Directive 93/42/EC

- High efficiency elements tested and verified to meet EN1822-1 filter class H14 requirements

- Meets NFPA 99 Requirements for vacuum filtration

Product Files

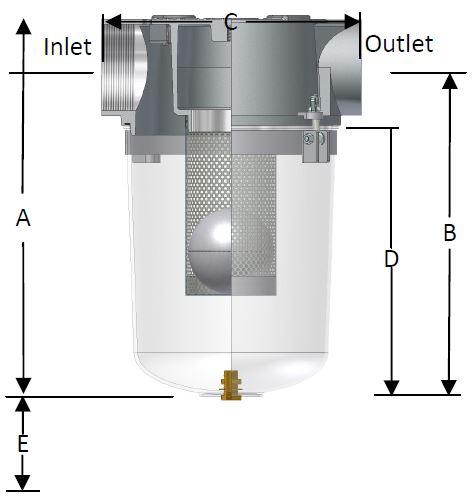

Medical Vacuum Line Moisture Trap and Filter

- Prohibit liquid and debris from damaging vacuum valves and pumps

- Easy visual inspection with see‐through housing

- Minimize piping costs with “T” style configuration

- Compact design for space restricted work areas•

- Inlet air with potentially harmful liquid and large particulate enters the housing and is separated by a baffling mechanism and directional air flow changes.

- The larger particles and liquid drops down and collects at the botiom of the separator.

- The float ball within the separator screen rises with the liquid level until max capacity and cuts off the flow thereby protecting the pump from damage.

- Float level port/switch

- Cast head protectve coatngs: stainless steel, epoxy finish, PTFE

- Heavy duty carbon steel buckets available

- Spool piece extender on select models

- Pressure drop gauge

- High impact, shater resistant, polycarbonate bucket

- Corrosion resistant cast aluminum head with integrated knock‐out baffle

- Cast head with tap hole guides for mountng brackets

- Stainless steel float ball for emergency shut off

- Clamp style T‐bolts standard

- Temperature ratngs: max 257°F (125°C)

- 1/2” drain

- 1/4” differental gauge ports

Submit Quote

Submit Quote View RFQ

View RFQ