Medical Gas Master Alarm

Medical Gas Master Alarm Panels are required by NFPA in most medical facilities to monitor life saftey source equipment such as medical vacuum system, medical air compressors, medical gas manifolds, and oxygen bulk farms. The Amico master alarms connect to source equipment via dry contacts on a closed circuit. The master alarm accepts low voltage signals from any brand of source equipment.

- Compatible with most pressure existing pressure switches (confirm before ordering)

- Use twisted, sheilded size 22 cable when installing (one pair per signal)

- A green LED indicator for normal and a red LED indicator for abnormal conditions

- Up to 60 functions in a standard con! guration

- LED Alarm lights utilized for long life

- Area Alarm Modules can be intermixed with Master Alarm Modules

- Maintenance mode for ease of trouble shooting

- Self diagnostic circuitry for added reliability

- Modules can be upgraded in the field to interface to a building management system or slave alarm via dry contacts

- Alarm buzzer in excess of 90 decibels

- All modules to be mounted on a hinged frame for easy accessibility

- Repeat alarm adjustable to 1, 12, or 24 hours or no-repeat

- Dry contacts for remote monitoring of high and low alarms and the distance between the master module and source equipment can be up to 10,000 ft.

General Specifications:

Features:

Each module shall be microprocessor based and field adjustable. Each signal contains a green LED indicator for normal and a red LED indicator for abnormal conditions. When a fault occurs, the green LED turns o" and the red LED illuminates, and the audible alarm sounds. The red LED until the front panel alarm mute button is pressed. After the alarm mute button is pressed, the red LED remains illuminated but does not # ash. The red indicator automatically turns on and the green LED illuminates when the fault is corrected. A repeat alarm function shall, when enabled, be capable of turning on the buzzer again, after a preset time, if the fault condition has not been rectified. A maintenance mode shall, when enabled, latch the alarms, requiring a

reset after the alarm condition has been rectified. This is to assist in tracking down wiring problems or faulty ! eld devices. The master alarm shall identify the last alarm condition by # ashing, while the already acknowledged alarm shows a continuous red signal. A repeat alarm function shall, when enabled, be capable of turning on the buzzer again, after a preset time, if the fault condition has not been rectified.

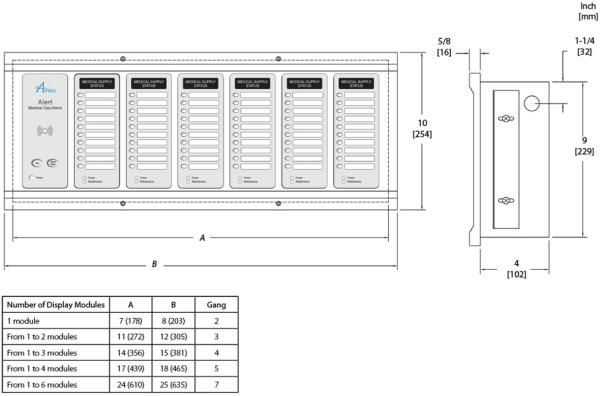

Each module shall handle 10 functions and up to 6 modules can be accommodated per standard box for a total of 60 functions. Master alarms shall be modular in construction and shall be capable of adding extra modules in the field. The Alarm system shall be a closed circuit self monitoring type. A green “POWER” light shall provide indication that the unit is energized. In addition “TEST” and “ALARM MUTE” buttons shall be easily accessible to operate and test the unit. Every module shall be ! eld upgradable to allow for interfacing to a building management system with the addition of an add-on circuit board which plugs into the master module. The box shall be fabricated from 18 gauge [1.3 mm] steel and the box mounting brackets shall be adjustable to accommodate for di" erent thickness of the wall. Input power to the Amico Alert-2 alarm is: 115 VAC to 220 VAC, 50 to 60 HZ.

The alarm is UL Listed. Amico products comply with NFPA-99, CSA Z7396.1 and CSA Z305.1

Features:

Each module shall be microprocessor based and field adjustable. Each signal contains a green LED indicator for normal and a red LED indicator for abnormal conditions. When a fault occurs, the green LED turns o" and the red LED illuminates, and the audible alarm sounds. The red LED until the front panel alarm mute button is pressed. After the alarm mute button is pressed, the red LED remains illuminated but does not # ash. The red indicator automatically turns on and the green LED illuminates when the fault is corrected. A repeat alarm function shall, when enabled, be capable of turning on the buzzer again, after a preset time, if the fault condition has not been rectified. A maintenance mode shall, when enabled, latch the alarms, requiring a

reset after the alarm condition has been rectified. This is to assist in tracking down wiring problems or faulty ! eld devices. The master alarm shall identify the last alarm condition by # ashing, while the already acknowledged alarm shows a continuous red signal. A repeat alarm function shall, when enabled, be capable of turning on the buzzer again, after a preset time, if the fault condition has not been rectified.

Each module shall handle 10 functions and up to 6 modules can be accommodated per standard box for a total of 60 functions. Master alarms shall be modular in construction and shall be capable of adding extra modules in the field. The Alarm system shall be a closed circuit self monitoring type. A green “POWER” light shall provide indication that the unit is energized. In addition “TEST” and “ALARM MUTE” buttons shall be easily accessible to operate and test the unit. Every module shall be ! eld upgradable to allow for interfacing to a building management system with the addition of an add-on circuit board which plugs into the master module. The box shall be fabricated from 18 gauge [1.3 mm] steel and the box mounting brackets shall be adjustable to accommodate for di" erent thickness of the wall. Input power to the Amico Alert-2 alarm is: 115 VAC to 220 VAC, 50 to 60 HZ.

The alarm is UL Listed. Amico products comply with NFPA-99, CSA Z7396.1 and CSA Z305.1

Submit Quote

Submit Quote View RFQ

View RFQ